Unlock unrivalled precision and accuracy

Meeting stricter tolerances, customer deadlines, and maintaining international quality standards does not have to be complex. Incorporating straightforward measures such as calibration can streamline processes, enhancing precision and efficiency along the way.

At Renishaw, we have produced a range of laser interferometer and ballbar measurement products. These allow you to assess, monitor and improve the static and dynamic performance of machine tools, motion stages, co-ordinate measuring machines (CMMs), automation, research and scientific applications.

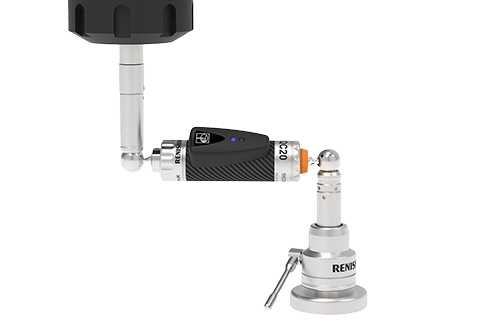

Renishaw’s Ball Bar System QC20W is a quick health check-up of your machine tool( CNC Lathes, VTLs, VMCs, HMCs etc.) It generates the Health report of CNC machine tools comprising of 14 types of errors like- Backlash, Servo mismatch, Sqaureness, Reversal Spikes, Cyclic Errors and many more. Shankara Industrial Corporation offers Service and sales of the equipment. Contact us for Pricing.

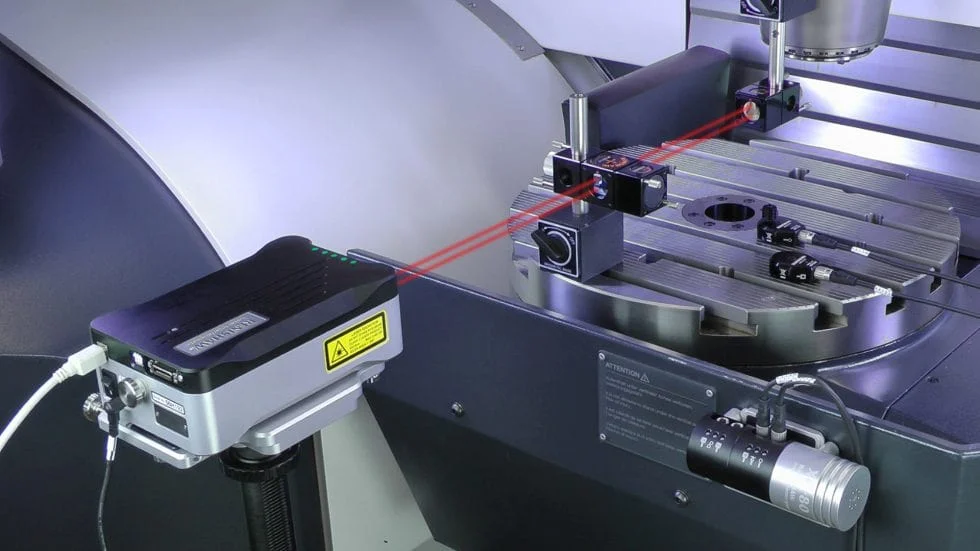

The Renishaw’s XL-80 laser interferometer is ideal for measuring and calibrating precision motion systems. With 0.05 ppm laser frequency accuracy, the XL-80 laser offers the ultimate high-performance measurement. M/s Shankara Industrial Corporation provides services for Laser Calibration for pitch error compensation for all type of CNC machines.

Why calibrate your machine?

Understanding and addressing errors in machines and motion systems is crucial for optimising performance.

Machine calibration and optimisation improves manufacturing standards, giving a competitive edge with quality, compliance and customer trust.

Increase productivity

Track machine position changes to enable maintenance forecasts, reducing machine downtime.

Enhanced performance

Capability insights

Confidently assign tasks to each machine using insights to ensure optimum yield.

Performance evidence

Boost customer confidence using custom reports and regular performance evaluation checks.

Scheduled maintenance

Effectively anticipate, implement, and optimise your machine maintenance schedules.

Quality compliance

Adhere to ISO 9000 standards by using traceable calibration methods.